FILTRATION: EFFICIENCY AND QUALITY IN INDUSTRIAL WATER TREATMENT

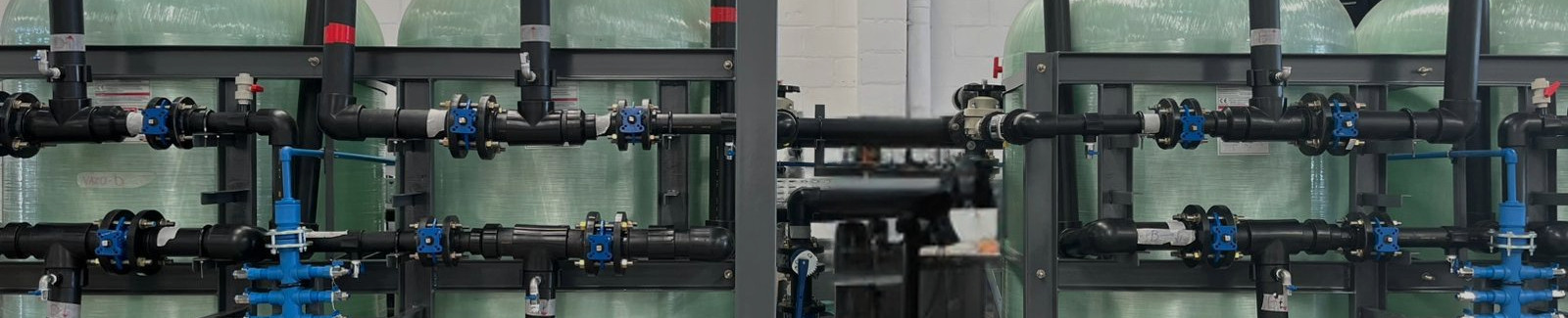

Filtration in water and effluent treatment is one of the most important stages in ensuring the removal of solid particles, impurities and contaminants that compromise water quality. At GIGWATER, we develop tailor-made industrial water filtration systems, ensuring purity, efficiency and compliance with the standards required by each production process.

With state-of-the-art technology and different types of water treatment filtration, our systems offer superior performance and lower operating costs for industries looking for high-standard solutions.

MAIN TYPES OF FILTERS USED

Each industrial process requires a specific level of filtration. For this reason, GIGWATER designs and manufactures different configurations, adapted to the needs of each client:

SAND FILTER

ACTIVATED CARBON FILTER

ZEOLITE FILTER

MULTIMEDIA FILTER

SECTORS THAT STAND OUT IN THE USE OF INDUSTRIAL FILTRATION

The filtration of water and industrial effluents is widely applied in different production segments that require strict control of water quality:

-

FOOD AND BEVERAGE INDUSTRY: Guarantees impurity-free water for processes and washing.

-

PHARMACEUTICAL AND COSMETICS SECTOR: Essential for achieving high purity standards.

-

MINING AND METALLURGY: Helps control turbidity and recover process water.

-

ENERGY AND OIL & GAS: Removes contaminants and protects boilers and cooling systems.

BENEFITS OF FILTRATION IN WATER TREATMENT

IMPROVING THE QUALITY OF TREATED WATER AND EFFLUENT

Adopting an industrial water filtration system from GIGWATER brings direct benefits to the operation: